Constant Systems One Shot Cell Disruptor

Constant Systems One Shot Cell Disruptor

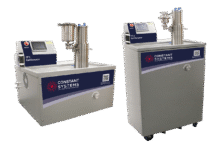

Compact, high-precision system designed for small-volume sample processing.

Precision Small-Volume Cell Lysis for Research Applications

The One Shot (OS) Cell Disruptor is a compact, high-precision system designed for small-volume sample processing and ideal for research laboratories seeking consistent, reproducible cell lysis.

With a footprint of approximately 500 mm², the OS sits comfortably on the benchtop, but is most effective when paired with its custom-designed mobile trolley. The trolley positions the unit at the optimal operating height and features full-swivel, lockable casters, ensuring safe and effortless movement within the laboratory.

The OS is capable of processing 0.5 mL to 8 mL per cycle, with an exceptionally low dead volume of <0.1 mL per process. For total sample volumes up to 24 mL, the OS is an excellent upgrade for users transitioning from small benchtop techniques such as bead beating or sonication, offering higher efficiency, superior reproducibility, and significantly improved control.

Like all Constant Systems instruments, the OS utilizes the company’s precise and fully scalable hydraulic control system, ensuring accurate and stable pressure delivery across the entire product range—from 0.5 mL single-prep samples to industrial-scale processing at 150 L/hour.

This precision guarantees that 99% of the sample is processed at the operator-defined pressure, resulting in reliable and repeatable outcomes. For most applications, a single process pass is sufficient, eliminating the need for multiple cycles.

The OS is suitable for processing a wide variety of sample types, including fluid, re-suspended, viscous, tissue, plant, and frozen materials.

Key Features & Specifications

- Simple, quick, and intuitive to operate

- Requires only a standard electrical supply—no compressed air or bottled gases

- No priming or purging necessary; air in the system is processed without affecting performance

- Built-in stainless steel spill tray for safe and easy cleanup

- Digital pressure display with precise control between 1–40 kpsi

- Capable of processing fluid, re-suspended, viscous, tissue, plant, and frozen samples

- Supplied collection cups can be moved directly to ice or freezer for temperature management

- Constant Systems’ hydraulic control ensures consistent, repeatable results, with 99% of the sample processed at the set pressure

- Fully enclosed system for safe operation

- Easy cleaning options:

- Flow-through cleaning using 70% ethanol, 1 M sodium hydroxide, or 1% Virkon

- Manual cleaning with removable components suitable for autoclaving or manual washing

- Product-contact materials: 316L stainless steel, F51 duplex (or equivalent), EPDM, GLF-PTFE, PEEK 450G

- Unit dimensions: 475 × 510 × 455 mm (D × W × H)

- Unit weight: 110 kg

- Electrical supply: Country-specific plug; standard single-phase via C15 or C20 connection

Ready to optimize your cell disruption workflow?

Our team is here to guide you in selecting the right Constant Systems model and configuration for your application.

Questions? Contact our product managers for more information.

Annika Garnås