Multifors 2

Multifors 2

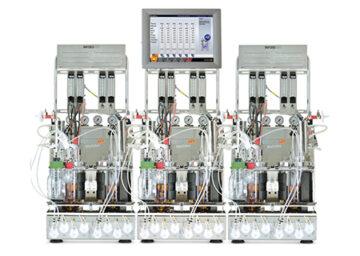

Multifors 2, parallel bioreactor – Big technology on a small scale

More results on a small surface? You get that with Multifors 2 with 2, 4 or 6 bioreactors in one instrument!

Multifors 2 is specially developed for multiple, parallel bioprocesses with small volumes. Together with the software IRIS, Multifors 2 provides a fast and statistically reliable way to generate and understand process data. Several choices of preconfigured packages and a wide selection of options make Multifors 2 an application-optimized choice for your microbial fermentation. Different cultivation strategies such as batch, fed-batch and continuous cultivation are possible.

INFORS HT has been a pioneer in this technology area for many years and their product and application specialists continuously improve and optimize the system to provide fast, parallel handling in the smallest possible space.

Key features:

- Faster results with optimized, parallel, managementFlexible and application-optimized configurations

- Space-saving, compact design

- Integrated OPC server for unlimited connections

- 100% aseptic sampling

- Accurate control of your bioprocess

- Clear path for scaling up

Mainly used for:

- Bacteria (E.coli, Pseudomomas, etc.)

- Fungi (Aspergillus, Streptomyces, etc.)

- Yeast (P. pastoris, Saccharomyces, etc.)

- Cultivation volume from 180 to 1000 mL

Applications:

- Process development

- Process optimization

- Scaling up

- Scaling down

- Statistical studies

- Process analytical technology (PAT)

- Media development

- Growth studies

- Toxicity tests

- High throughput screening

Control system with touch screen and integrated OPC server

Bioprocess control starts with the quality and flexibility of the local control unit. The touch screen for Multifors 2 provides accurate and safe measurement, control and communication with the monitoring software. The touch screen controller can control up to 6 bioreactors. The key parameters for all six vessels are displayed in an overview menu on the main page but each unit can be controlled completely separately.

Up to 24 parameters per vessel:

- Temperature

- Agitator speed

- pH control

- pO2 control

- Antifoam/level

- Feed

- Gas mix

- Gas flow

- + 16 free channels

Space-saving, compact base unit

An extremely compact stand-alone unit with two completely individual bioreactors in a single base unit. Up to six bioreactors can be connected to one and the same control unit and only need about 1.2 m of bench space. 2 or 3 units can be assembled, disassembled and combined according to prevailing needs. This provides more flexibility in terms of placement in the laboratory and the ability to add more units and/or control units as needs change.

Fully equipped vessels

Multifors 2 has fully equipped, replaceable vessels with working volumes from 180 up to 1 liter with the same characteristics as for larger systems. The top plate in stainless 316L steel has many ports with industry standard Pg13.5 ports that make it possible to use a wide range of sensors (antifoam, optical density, pH, pO2, redox, capacitance, etc.). Rushton impellers and ring spars for high gas flows are included as standard. The vessels can be configured in different ways with the help of accessories such as impellers, spargers and special accessories. A wide selection of other accessories is on the program to cover practically all applications.

The vessel’s construction and design (without welded parts) makes Multifors 2 ideal for applications where strict GMP requirements apply.

100% aseptic stirring system

Multifors 2’s stirrer system is designed specifically for parallel, aseptic, small-volume bioprocesses. It reduces the risk of contamination and provides extra space for many sensors on the top plate. Together with the Iris software for parallel bioprocesses, there are no limits to your cultivation strategy and further process understanding.

The operation takes place from the bottom and is both start-up and reliable with a stirring speed of up to 1200 rpm. Mixing and mass transfer characteristics are scalable to standard bench-scale bioreactors.

A simple test shows the power of the magnetic transmission; pure glycerol can be grown continuously at 1100 rpm (at room temperature without gas addition) without the clutch slipping or the engine being overloaded.

Open system for gas addition with up to 5 mass flow controllers

INFORS HT’s open gas system provides accurate gas mixing and flow control for very accurate pO2 control. The system provides a very high KLa that is comparable to large systems to make scaling up as easy as possible. Any combination of air, O2, N2 or CO2 as single gas can be directed to sparger or headspace.

We recommend pO2 control as standard for microbial culture; air, O2 to sparger via mass flow control.

More reproducible and accurate results thanks to the thermodynamic condenser

Liquid evaporation from the bioreactor vessel can be problematic at all scales, but is especially critical at small culture volumes. The construction of INFORS HT’s condenser means that the moisture in the outgoing gas is condensed with maximum efficiency.

Time-saving high-precision pumps

It includes four high-precision pumps per vessel; feed, acid, base and antifoam/level/harvest as standard. This makes Multifors 2 ready for applications such as fed batch and continuous cultivation directly from the package.

The pump heads are mounted on a removable plate and can be removed in groups of four to be autoclaved together with the vessel. This significantly reduces handling time as hose does not need to be assembled and adjusted for use. Handling errors due to misplaced pumps and hoses are hereby completely eliminated through this unique design. The only thing required is to mount the plate back in place. Automatic emptying, filling of the hose and calibration of the pumps make it even easier.

Temperature control with high precision

The aluminum heating block with integrated cooling loop replaces the need for a double-walled vessel or heating jacket. It simplifies handling and provides full insight into your bioprocess. Temperature range from approx. 5° above cooling water temperature to 60°C.

Super Safe Sampler – 100% aseptic and absolutely hygienic sampling

Super Safe Sampler INFORS HT’s Super Safe Sampler gives you the opportunity to take small sample quantities without spillage. It helps with more accurate results, especially in small-scale bioprocesses with minimal liquid loss. The true aseptic design makes contamination during sample handling impossible.

Annika Garnås